鎳基高溫合金在 600 ℃ 以上具有出色的組織穩(wěn)定性��、抗氧化性能����、抗熱腐蝕性能及力學(xué)性能����,是熱端部件制造的重要材料���,在航空發(fā)動(dòng)機(jī)與燃?xì)廨啓C(jī)中具有廣泛應(yīng)用,傳統(tǒng)制備工藝主要為鑄造�����、鍛造及粉末冶金[1-2]�����。隨著航空發(fā)動(dòng)機(jī)與燃?xì)廨啓C(jī)的快速發(fā)展�����,鎳基高溫合金零件表現(xiàn)出復(fù)雜化�、輕量化、一體化的發(fā)展趨勢(shì)����,對(duì)鎳基高溫合金制備工藝提出了新的需求。

增材制造技術(shù)是一種近凈成形工藝����,通過(guò)激光、電子束��、電弧等高能束熱源逐層熔化粉末或絲材���,以逐層堆疊的方式實(shí)現(xiàn)零件制備��。常用的鎳基高溫合金增材制造工藝主要有激光粉末床熔融(laser powder bed fusion���, LPBF) 、 電 子 束 熔 融(electron beam melting�����, EBM)��、激光直接熔化沉積(laser direct energy deposition�, LDED)和電弧增材制造(wire arc additive manufacturing, WAAM)[3-4]����。

相較于傳統(tǒng)工藝,增材制造技術(shù)更適合進(jìn)行復(fù)雜結(jié)構(gòu)零件制造�����。增材制造技術(shù)與拓?fù)鋬?yōu)化、集成化設(shè)計(jì)等設(shè)計(jì)方法相結(jié)合可提高設(shè)計(jì)自由度����,在促進(jìn)裝備輕量化的同時(shí),還能縮短加工周期�。羅羅公司使用增材制造技術(shù),使零件制造周期縮短了 30%[5]����。

其為 Trent XWB-84 發(fā)動(dòng)機(jī)生產(chǎn)的低壓渦輪,質(zhì)量減輕約 40%[6]��。利勃海爾公司采用增材制造替代傳統(tǒng)制造技術(shù)���,使零件質(zhì)量減少 35%�,零件數(shù)量減少 10 個(gè)����,生產(chǎn)時(shí)間縮短 75%[5]。GE 公司的增材制造 T25 傳感器外殼將 10 個(gè)零件合并為 1 個(gè)零件����,使傳感器精度提高了 30%。2015 年,該零件成為首個(gè)通過(guò)美國(guó)聯(lián)邦航空局適航認(rèn)證的增材制造航空發(fā)動(dòng)機(jī)零件[7-8]�����。此外��,增材制造過(guò)程冷卻速度快��、熔池固液界面溫度梯度大�,不僅易形成沿沉積方向連續(xù)外延生長(zhǎng)的柱狀晶��,還可減少凝固過(guò)程中的成分偏析及組織粗大問(wèn)題����,適用于渦輪葉片修復(fù)。2001 年����,瑞士洛桑聯(lián)邦理工學(xué)院率先使用激光直接熔化沉積技術(shù)對(duì) CMSX-4 合金葉片進(jìn)行了修復(fù)[9-11]。美國(guó)普渡大學(xué)的一項(xiàng)研究指出���,相較于更換新葉片�,采用增材制造技術(shù)修復(fù)舊葉片�����,可減少36% 的能源消耗[12]。因此�,增材制造技術(shù)已逐漸成為具有良好可焊性鎳基高溫合金零件快速制造及修復(fù)的重要技術(shù)途徑。

本文對(duì)增材制造鎳基高溫合金在航空發(fā)動(dòng)機(jī)與燃?xì)廨啓C(jī)中的研究應(yīng)用現(xiàn)狀進(jìn)行綜述���,闡述增材制造鎳基高溫合金的顯微組織特征及常見冶金缺陷的形成原因與控制方法�,總結(jié)增材制造 GH3536����、GH3625 和 GH4169 的室溫/高溫拉伸性能,介紹航空發(fā)動(dòng)機(jī)及燃?xì)廨啓C(jī)中增材制造鎳基高溫合金零件的應(yīng)用情況�。基于國(guó)內(nèi)外研究現(xiàn)狀�����,對(duì)今后的重要發(fā)展方向進(jìn)行展望����。

1 、增材制造鎳基高溫合金顯微組織

增材制造過(guò)程溫度梯度大�、冷卻速度快,與傳統(tǒng)工藝制備鎳基高溫合金的顯微組織存在差異�。采用不同增材制造方法成形的鎳基高溫合金的晶粒形貌均主要由沿沉積方向外延生長(zhǎng)的柱狀晶與少量等軸晶構(gòu)成,具有明顯的各向異性。直接能量沉積過(guò)程熱量通過(guò)基板或已沉積部分散失����,故柱狀晶通常垂直于基板并稍向激光掃描方向傾斜。粉末床熔融成形過(guò)程熔池尺寸較小�、對(duì)流更為劇烈,故柱狀晶生長(zhǎng)方向與直接能量沉積相比更為復(fù)雜[5]���。

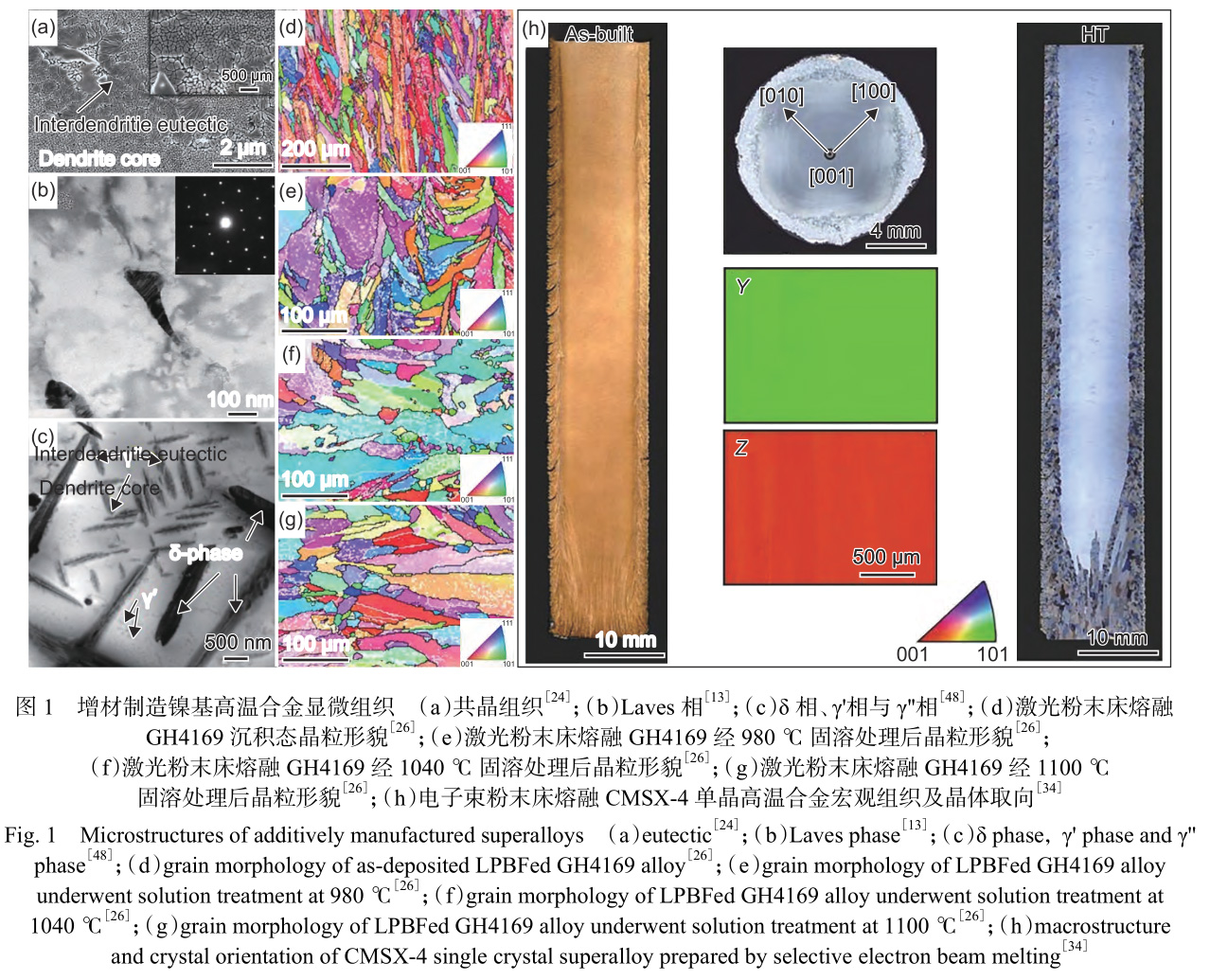

增材制造鎳基高溫合金的沉積態(tài)組織通常由 γ 相、γ'相�����、共晶組織�、Laves 相、金屬間化合物和碳化物等組成(圖 1(a)~(c))[13]�。Xu 等[14] 采用電弧增材制造技術(shù)制備的 GH4169 合金由沿沉積方向生長(zhǎng)的粗大的柱狀晶組成,柱狀晶的長(zhǎng)度和寬度分別約為 11 mm 與 0.8 mm�。Tayon 等[15] 對(duì)電子束熔融 GH4169 合金的研究結(jié)果表明,沉積態(tài)組織具有較強(qiáng)的織構(gòu)���,在 1190 ℃ 下進(jìn)行熱處理后柱狀晶轉(zhuǎn)變?yōu)榈容S晶���,織構(gòu)顯著減弱。有研究在激光粉末床熔融成形 GH4169 合金的沉積態(tài)組織中發(fā)現(xiàn)了脆性金屬間化合物 δ 相和 Laves 相[16-17],還有報(bào)道指出激光直接熔化沉積 GH4169 合金中存在碳化物和 Laves 相[18]��。激光粉末床熔融成形 GH3536 合金的沉積態(tài)組織主要由單相奧氏體構(gòu)成�,晶界基本無(wú)析出物[19-20]。激光粉末床熔融成形 GH3625 合金沉積態(tài)組織主要由 γ 相基體�����、金屬間化合物和 Laves相構(gòu)成[21-23]��。Wang 等[24] 對(duì)激光直接熔化沉積IC10 合金的研究表明�����,凝固過(guò)程中的成分偏析會(huì)導(dǎo)致晶界形成共晶組織���。

非平衡相及 Laves 相的存在會(huì)對(duì)材料性能造成不良影響�����,因此要對(duì)成形合金進(jìn)行熱處理/熱等靜壓處理����,以改善其內(nèi)部質(zhì)量與顯微組織��。增材制造 GH4169 合金通常要進(jìn)行固溶處理,使 δ 相和 Laves相充分溶解�,促進(jìn)后續(xù)時(shí)效處理中 γ' 相的析出。由于 Nb 原子擴(kuò)散能力較差�����,為了使 δ 相充分溶解����,增材制造 GH4169 合金的固溶溫度一般要高于鍛件的固溶處理溫度[25]。Ni 等[26] 研究了固溶溫度對(duì)激光粉末床熔融成形 GH4169 合金晶粒形貌的影響后指出����,經(jīng) 980 ℃ 固溶處理后��,柱狀晶部分轉(zhuǎn)化為等軸晶�,導(dǎo)致了晶粒尺寸的減小��;經(jīng) 1040 ℃ 和1100 ℃ 固溶處理后���,柱狀晶完全轉(zhuǎn)化為等軸晶����,不同熱處理狀態(tài)下 GH4169 合金的晶粒形貌如圖 1(d)~(g)所示。激光粉末床熔融成形 GH3536 合金在經(jīng)過(guò)熱處理后�����,熔池邊界消失���,并伴隨有等軸晶形成[27]�����,其在經(jīng)過(guò)熱等靜壓處理后����,晶粒長(zhǎng)大并轉(zhuǎn)變?yōu)榈容S晶���,且晶界與晶粒內(nèi)部的溶質(zhì)元素?cái)U(kuò)散會(huì)導(dǎo)致碳化物形成

[19-20,28]�����。有研究指出��,激光粉末床熔融 GH3625 合金在 700 ℃ 固溶處理?xiàng)l件下�����,顯微 組 織 基 本 不 發(fā) 生 變 化 �。 當(dāng) 固 溶 溫 度 升 高 至1000 ℃ 時(shí),熔池邊界消失��,有碳化物在晶界析出��。經(jīng)過(guò) 1150 ℃ 熱處理后�,晶粒進(jìn)一步長(zhǎng)大,且晶界處的碳化物也會(huì)明顯發(fā)生粗化[29]���。Wang 等[30] 對(duì)激光直接熔化沉積 GH3230 合金的研究表明����,合金沉積態(tài)組織中存在 M23C6 與 M6C 兩種碳化物�。經(jīng)固溶處理后�,碳化物含量與尺寸均明顯減少,且M23C6 碳化物完全消失����。黃文普等[31] 發(fā)現(xiàn)激光粉末床熔融成形 K4202 合金經(jīng)固溶+時(shí)效處理后發(fā)生再結(jié)晶,且晶界和晶內(nèi)均有碳化物析出�。

增材制造鎳基高溫合金的定向生長(zhǎng)特性,使其成為單晶高溫合金制備與修復(fù)的重要手段���。在單晶高溫合金制備方面���,Jodi 等[32] 使用激光粉末床熔融技術(shù)��,通過(guò)平頂光在多晶合金基體上實(shí)現(xiàn)了單晶合金的制備���。近年來(lái),隨著電子束熔融技術(shù)的發(fā)展�,采用該方法進(jìn)行單晶高溫合金制備成為研究重點(diǎn)之一。Ramsperger 等[33] 首次使用電子束粉末床熔 融 技 術(shù) 制 備 了 單 晶 高 溫 合 金 �����。 K?rner 等[34]制備的 CMSX-4 單晶高溫合金在經(jīng)過(guò)熱處理后可達(dá)到與鑄件相當(dāng)?shù)牧W(xué)性能�,某些性能甚至優(yōu)于鑄件(圖 1(h))。Fernandez-Zelaia 等[35] 研究了工藝參數(shù)對(duì)高溫合金顯微組織的影響�����,發(fā)現(xiàn)較高的能量輸入可促進(jìn)單晶的形成����。Chauvet 等[36] 在預(yù)熱溫度約 1020 ℃ 條件下,在不銹鋼基板上制備了無(wú)裂紋的單晶高溫合金��。林峰教授課題組[37] 采用電子束粉末床熔融技術(shù)在不銹鋼基板上制備了 Inconel738 單晶高溫合金,由于單晶的形成對(duì)凝固條件具有很強(qiáng)的依賴性���,因此制備不同尺寸的單晶高溫合金需要使用不同的工藝參數(shù)�。在單晶高溫合金修復(fù)領(lǐng)域����,洛桑聯(lián)邦理工學(xué)院研究了激光直接熔化沉積工藝參數(shù)對(duì) CMSX-4 合金組織影響規(guī)律,并對(duì)CMSX-4 合金葉片進(jìn)行了修復(fù)[8-10]�����。Liang 等[38-42]研究了激光快速凝固過(guò)程中單晶高溫合金的凝固路徑�,分析了工藝參數(shù)對(duì)單晶高溫合金顯微組織的影響規(guī)律,并根據(jù)工藝優(yōu)化結(jié)果在單晶基體上成功制備出具有良好定向性的單晶高溫合金�。中國(guó)科學(xué)院金屬研究所分析了熱處理對(duì)增材制造單晶高溫合金顯微組織的影響,并通過(guò)調(diào)整工藝參數(shù)實(shí)現(xiàn)了DD32 單晶渦輪葉片的修復(fù)[43-44]���。Rottwinkel 等[45]通過(guò)在 CMSX-4 單晶高溫合金修復(fù)區(qū)周圍施加預(yù)熱及對(duì)底部進(jìn)行水冷,實(shí)現(xiàn)了熔池?zé)崃鞣较虻目刂?��,從而保證了修復(fù)區(qū)單晶組織的完整性�����。Wang等[46] 對(duì)比了激光與等離子弧對(duì) DD407 單晶高溫合金的修復(fù)效果��,發(fā)現(xiàn)兩種工藝方法均可獲得定向生長(zhǎng)的單晶組織����,但等離子弧修復(fù)后的熱影響區(qū)更大。Zhang 等[47] 利用同步輻射技術(shù)發(fā)現(xiàn)了 DD5 單晶高溫合金在激光快速熔凝過(guò)程中的晶體轉(zhuǎn)動(dòng)現(xiàn)象�,為單晶高溫合金增材制造及修復(fù)過(guò)程中的晶體取向控制提供了理論依據(jù)。

2��、 增材制造鎳基高溫合金冶金缺陷

孔隙和裂紋是增材制造鎳基高溫合金中較為常見的冶金缺陷��?�?紫兜男纬稍蛑饕性霾闹圃爝^(guò)程中環(huán)境及原材料粉末帶來(lái)氣體形成的氣孔�,凝固過(guò)程中液態(tài)金屬收縮形成的孔洞及未完全熔化粉末顆粒之間的孔隙。對(duì)于粉末床熔融工藝�,粉末顆粒間的孔隙也可能導(dǎo)致出現(xiàn)氣孔[5,49]。增材制造鎳基高溫合金中的氣孔難以避免����,但是可通過(guò)優(yōu)化增材制造工藝參數(shù)、控制原材料粉末質(zhì)量�����、降低成形過(guò)程的氧含量及熱等靜壓等手段減小氣孔率。對(duì)于未融化粉末導(dǎo)致的孔隙���,可通過(guò)適當(dāng)增加輸入能量避免[50]�。Tomus 等[27] 采用熱等靜壓消除了激光粉末床熔融 GH3536 合金內(nèi)部孔隙��,提高了材料的室溫伸長(zhǎng)率�����。Han 等[51] 對(duì)激光粉末床熔融GH3536 合金進(jìn)行了熱等靜壓處理�,消除了材料內(nèi)部的孔隙與微裂紋,改善了合金的疲勞性能��,但同時(shí)也導(dǎo)致了抗拉強(qiáng)度與屈服強(qiáng)度的下降�。

開裂是目前限制增材制造技術(shù)在鎳基高溫合金制備中應(yīng)用的主要障礙,增材制造合金裂紋形成機(jī)制主要有三種[52-53]:(1)凝固裂紋:凝固裂紋形成于熔池凝固的最后階段����,在該階段液相充形困難,凝固收縮引起的應(yīng)力使枝晶間的液膜被撕裂����,導(dǎo)致裂紋出現(xiàn)(圖 2(a))���;(2)液化裂紋:液化裂紋形成于后續(xù)沉積過(guò)程中���,枝晶間的低熔點(diǎn)析出物或共晶組織在后續(xù)沉積熱循環(huán)中熔化形成液膜�����,液膜在內(nèi)應(yīng)力作用下被撕裂形成裂紋(圖 2(b))��;(3)固態(tài)裂紋:固態(tài)裂紋也是在后續(xù)沉積中形成的����,但固態(tài)裂紋的形成是由于內(nèi)應(yīng)力超過(guò)了固體材料的抗拉強(qiáng)度導(dǎo)致的���,未出現(xiàn)局部熔化(圖 2(c))��。晶界結(jié)構(gòu)�、化學(xué)成分�����、成分偏析�、晶粒尺寸及內(nèi)應(yīng)力等都會(huì)對(duì)增材制造鎳基高溫合金裂紋的形成造成影響。凝固過(guò)程中大角度晶界處殘留的液膜較多、界面能較高�����,易發(fā)生開裂�����。與大角度晶界相比�����,小角度晶界具有更好的穩(wěn)定性��,開裂傾向較低[54-55]�。Chauvet 等[56]的研究表明,當(dāng)晶界的取向差角大于 15°時(shí)�����,易沿晶界形成裂紋(圖 2(d)�����、(e))����。Guo 等[52] 對(duì)激光直接熔化沉積 GH3536 合金的開裂行為進(jìn)行研究后發(fā)現(xiàn)�����,晶界取向差角在 25°~45°之間時(shí),晶界的界面能較高�����,因此更易開裂����。合金的化學(xué)成分與凝固末期的成分偏析會(huì)導(dǎo)致凝固溫度范圍增大、晶界液膜存在時(shí)間延長(zhǎng)�����、阻礙液相填充枝晶間空隙并促進(jìn)晶間低熔點(diǎn)相形成��,從而增加開裂傾向[57-59]�����。合金的凝固溫度范圍越大��,越易形成凝固裂紋[60]。激光直接熔化沉積 GH3536 合金裂紋附近區(qū)域的化學(xué)元素分布如圖 2(f)所示�。Cloots 等[61] 認(rèn)為成分偏析是導(dǎo)致激光粉末床熔融 IN738LC 合金開裂的主要因素之一。在成分偏析作用下�,晶界富集的元素不僅會(huì)阻礙液相流動(dòng),還可能削弱材料強(qiáng)度����,從而增大了材料開裂傾向[62-63]。此外�����,B 等低熔點(diǎn)元素在晶界的富集會(huì)增大凝固溫度區(qū)間和液膜存在時(shí)間�����,進(jìn)而促進(jìn)裂紋形成[56,64]����。Zhou 等[65] 對(duì)激光直接熔化沉積單晶高溫合金的研究結(jié)果顯示,枝晶間的碳化物和縮孔導(dǎo)致了凝固裂紋的萌生����,而低熔點(diǎn)化合物則引起了液化裂紋的形成。有研究認(rèn)為 C 和 Mo 元素在凝固過(guò)程中的偏析促進(jìn)了低熔點(diǎn)液膜的形成�����,導(dǎo)致激光直接熔化沉積 GH3536 合金發(fā)生開裂[52]。

針對(duì)裂紋形成原因��,可通過(guò)控制成形工藝����、調(diào)整合金成分及熱等靜壓等手段抑制或消除增材制造鎳基高溫合金中的裂紋����。凝固裂紋及液化裂紋形成機(jī)理示意圖分別如圖 2(g)、(h)所示�����。在成形工藝控制方面�����,張潔等[22] 指出���,基板預(yù)熱可降低激光粉末床熔融 GH3625 殘余應(yīng)力�����,從而抑制裂紋產(chǎn)生��。當(dāng)預(yù)熱溫度為 300 ℃ 時(shí)���,裂紋數(shù)量最少��。Kontis等[64] 通過(guò)調(diào)整電子束粉末床熔融工藝參數(shù)獲得了較大的晶界面積與較小晶粒尺寸�����,使熱應(yīng)力在晶界上分布更為均勻���,同時(shí),調(diào)節(jié)工藝參數(shù)還可降低成分偏析��,抑制硼化物的形成���;通過(guò)以上途徑��,改善了鎳基高溫合金的開裂傾向����。Xu 等[66] 研究了掃描策略對(duì)激光粉末床熔融 Inconel 738 合金開裂傾向的影響�����,發(fā)現(xiàn)相鄰兩層的掃描方向每次旋轉(zhuǎn) 67°可促進(jìn)等軸晶形成,有效抑制裂紋形成�,獲得良好的力學(xué)性能。對(duì)于可焊性較差的鎳基高溫合金��,僅調(diào)整工藝參數(shù)難以完全防止開裂���,還需對(duì)合金成分進(jìn)行調(diào)整�����。Tomus 等[67] 指出,降低 Si��、C 元素含量可改善激光粉末床熔融 GH3536 合金的抗開裂能力����。Harrison 等[68] 通過(guò)增加固溶強(qiáng)化元素、減少雜質(zhì)元素��,降低了 GH3536 合金在激光粉末床熔融

成形過(guò)程中的開裂傾向��,其研究結(jié)果顯示����,GH3536合金在經(jīng)過(guò)成分調(diào)整后�����,裂紋密度下降了約 65%�����,且高溫拉伸強(qiáng)度顯著升高��。Tang 等[69] 研究了合金成分�、成形性與力學(xué)性能之間的關(guān)系�����,并在此基礎(chǔ)上設(shè)計(jì)了 ABD-850AM 與 ABD-900AM 兩種高性能����、無(wú)裂紋的新型增材制造用鎳基高溫合金,他們認(rèn)為通過(guò)降低合金凝固溫度區(qū)間�、減少晶界析出物與低熔點(diǎn)共晶組織、提高合金的高溫塑性等手段可抑制增材制造鎳基高溫合金中的裂紋形成��。此外,細(xì)化晶?����?墒姑總€(gè)晶界承受的局部應(yīng)變減小��,并提高液相的充形能力���,從而增強(qiáng)合金的抗開裂能力[52]�����。

Han 等[70] 通過(guò)向 GH3536 合金中加入納米 TiC 顆粒�����,促進(jìn)凝固過(guò)程中的異質(zhì)形核���,使小角度晶界增多�,減輕了粉末床熔融 GH3536 合金的開裂傾向。Cheng 等[71] 在 GH3536 合金粉末表面采用原位化學(xué)合成方法制備了 Y2O3 涂層�,使用表面改性后粉末為原材料進(jìn)行激光粉末床熔融成形,Y2O3 顆粒促進(jìn)了凝固過(guò)程中的異質(zhì)形核��,形成了細(xì)小的組織,有效抑制了裂紋的萌生與擴(kuò)展�。

3 、增材制造典型鎳基高溫合金拉伸性能

目前�,GH3536、GH4169 和 GH3625 合金的增材制造工藝相對(duì)較為成熟����,易獲得致密無(wú)開裂樣品。增材制造鎳基高溫合金顯微組織的各向異性導(dǎo)致其力學(xué)性能具有明顯的各向異性�����,熱處理可顯著改善力學(xué)性能�����。增材制造鎳基高溫合金的室溫和高溫拉伸性能普遍高于鑄造合金��,但低于鍛造合金��,部分合金的力學(xué)性能可達(dá)到甚至超過(guò)鍛件的力學(xué)性能[16�,72]。Wang 等[73] 對(duì)比了激光粉末床熔融成形 GH3536 合金與熱鍛 GH3536 合金的拉伸性能�,發(fā)現(xiàn)激光粉末床熔融成形 GH3536 合金的強(qiáng)度高于熱鍛合金,但斷后伸長(zhǎng)率小于熱鍛合金��。Wang等[74] 制備的激光粉末床熔融成形 GH3625 合金具有與鍛造 GH3625 合金相近的拉伸性能。西北工業(yè)大學(xué)的研究結(jié)果顯示����,激光直接熔化沉積 GH4169

合金熱處理后的力學(xué)性能可滿足鍛件標(biāo)準(zhǔn)[75]。

Str??ner 等[76] 發(fā)現(xiàn)經(jīng)過(guò)均勻化處理后的激光粉末床熔融成形 GH4169 合金同鍛件性能相當(dāng)�����。激光粉末床熔融成形 GH3536 合金經(jīng)固溶(950 ℃ 保溫3 h 后空冷)與熱等靜壓處理(1125 ℃���、110 MPa 保溫 4 h 爐冷)后�����,室溫抗拉強(qiáng)度和伸長(zhǎng)率分別可達(dá)750 MPa 與 45%~50%�����。隨著測(cè)試溫度升高���,抗拉強(qiáng)度逐漸下降����,但伸長(zhǎng)率則基本不變。當(dāng)測(cè)試溫度超過(guò) 600 ℃ 后,抗拉強(qiáng)度和伸長(zhǎng)率均出現(xiàn)下降��;但當(dāng)測(cè)試溫度升高至 815 ℃ 后�,雖然抗拉強(qiáng)度仍然降低,但伸長(zhǎng)率卻有所升高[19]�。Sanchez-Mata 等[77]的研究結(jié)果表明,GH3536 合金沉積態(tài)的橫向抗拉強(qiáng)度�、屈服強(qiáng)度和伸長(zhǎng)率分別為 924.7、790.2 MPa和 25.7%��,縱向抗拉強(qiáng)度�����、屈服強(qiáng)度和伸長(zhǎng)率分別為 777.1��、662.8 MPa 和 22.3%���;在 1177 ℃ 下保溫2 h 空冷固溶處理后�,橫向抗拉強(qiáng)度�����、屈服強(qiáng)度和伸長(zhǎng)率分別為 792�、384.8 MPa 和 50.3%���,縱向抗拉強(qiáng)度、屈服強(qiáng)度和伸長(zhǎng)率分別為 728.3�����、412.8 MPa 和43.4%�����。在相同的熱處理制度下�����,Montero-Sistiaga等[78] 的研究結(jié)果顯示����,GH3536 合金的橫向抗拉強(qiáng)度、屈服強(qiáng)度和伸長(zhǎng)率分別為 709.5��、325.5 MPa 和44.3%���,縱向抗拉強(qiáng)度���、屈服強(qiáng)度和伸長(zhǎng)率分別為662.2��、320.5 MPa 和 44.9%。其研究結(jié)果還表明����,GH3536 合金沉積態(tài)的橫向抗拉強(qiáng)度、屈服強(qiáng)度和伸長(zhǎng)率分別為 787.5�����、552 MPa 和 31.5%�����,縱向抗拉強(qiáng)度�����、屈服強(qiáng)度和長(zhǎng)伸率分別為 494.3�����、682.2 MPa和 36.9%�;經(jīng) 800 ℃ 下保溫 2 h 空冷固溶處理后,材料的橫向抗拉強(qiáng)度�、屈服強(qiáng)度和伸長(zhǎng)率分別為798.1�����、508.3 MPa 和 31.8%�,縱向抗拉強(qiáng)度����、屈服強(qiáng)度和伸長(zhǎng)率分別為 728.3、484.4 MPa 和 36.3%[78]���。

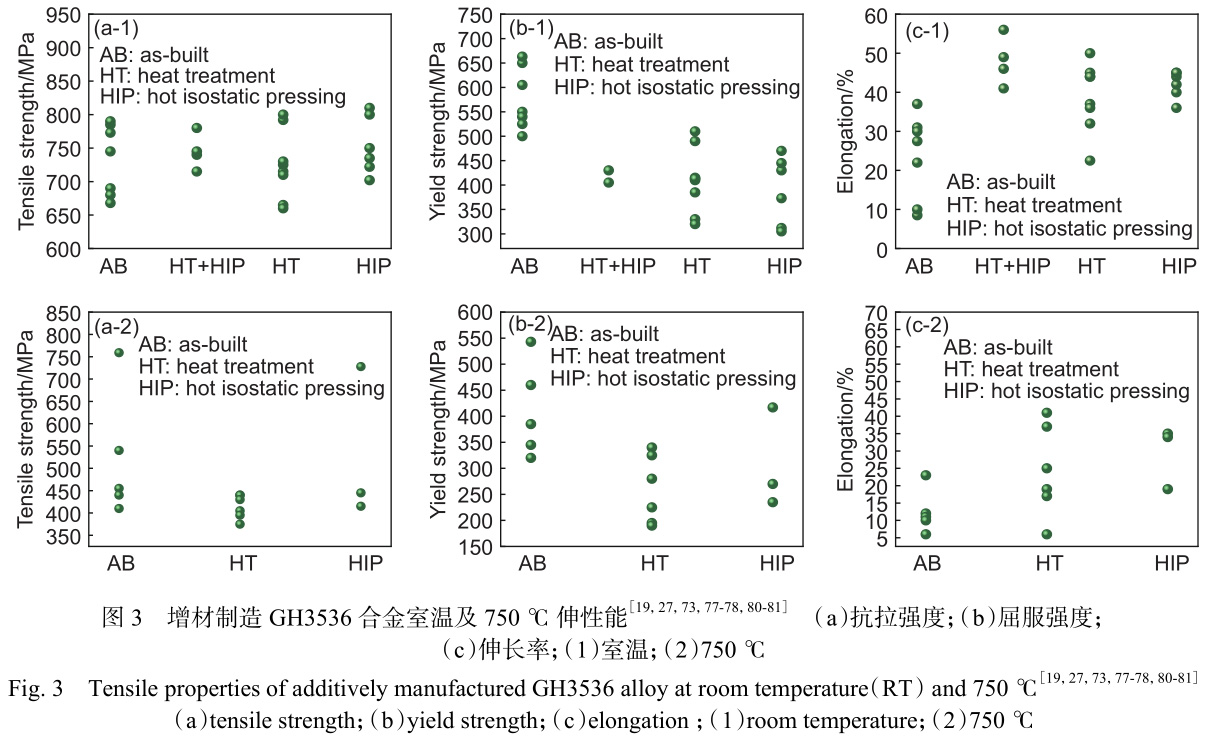

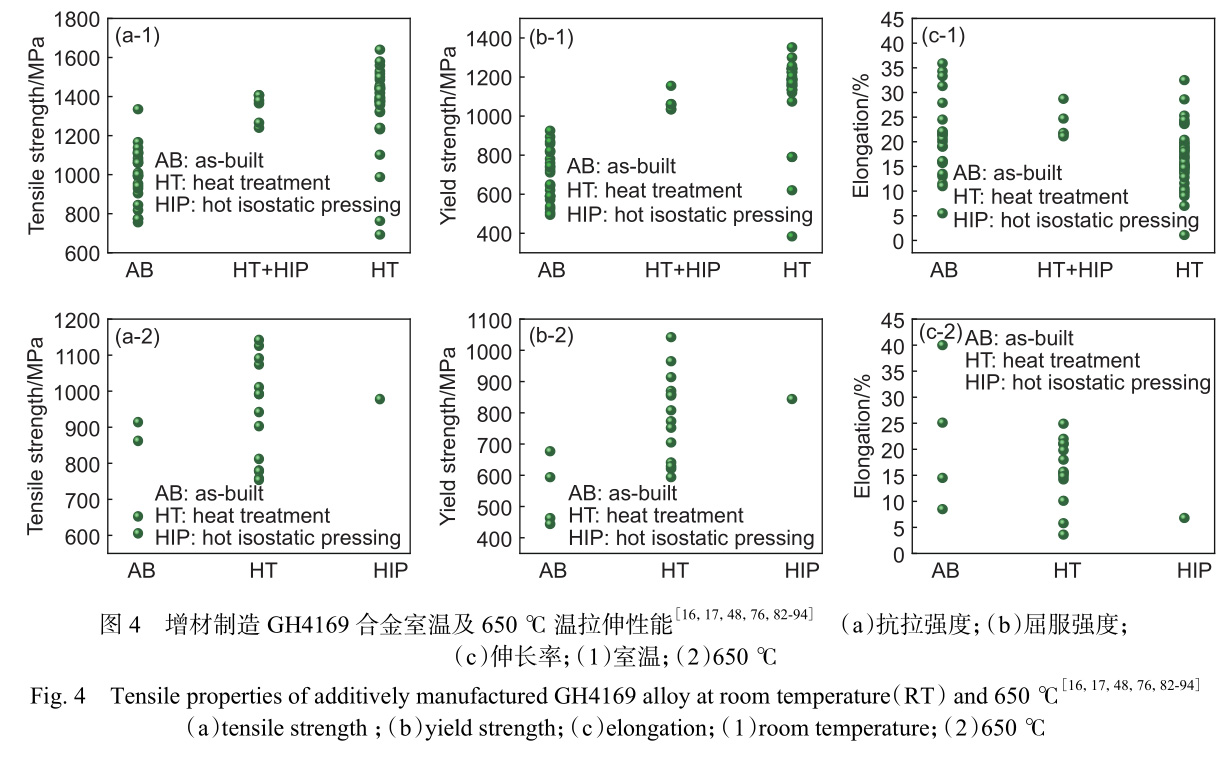

激光粉末床熔融成形 GH3625 合金的沉積態(tài)抗拉強(qiáng)度�、屈服強(qiáng)度和伸長(zhǎng)率分別為(925±13)����、(652±10) MPa 和(32±3)%��;經(jīng) 900 ℃ 保溫 1 h 固溶處理后�����,抗拉強(qiáng)度、屈服強(qiáng)度和伸長(zhǎng)率分別為(869±7)����、(567±15) MPa 和(38±1)%��;經(jīng) 1100 ℃ 保溫 1 h 固溶處理后�,抗拉強(qiáng)度��、屈服強(qiáng)度和伸長(zhǎng)率分別為(886±11)����、(409±14) MPa 和(56±5)%����。對(duì)激光直接熔化沉積 GH3625 合金,其沉積態(tài)抗拉強(qiáng)度�、屈服強(qiáng)度和伸長(zhǎng)率分別(1073±5)、(723±23) MPa 和(26±2)%�;經(jīng) 900 ℃ 保溫 1 h 固溶處理后,抗拉強(qiáng)度��、屈服強(qiáng)度和伸長(zhǎng)率分別為(1084±2)�、(654±15)MPa 和(27±2)%;經(jīng) 1100 ℃ 保溫 1 h 固溶處理后�,抗拉強(qiáng)度、屈服強(qiáng)度和伸長(zhǎng)率分別為(991±13)���、(532±22) MPa 和(43±1)%[79]�����。圖 3~圖 5 總結(jié)了部分文獻(xiàn)中增材制造 GH3536��、GH4169 和 GH3625合金沉積態(tài)及經(jīng)不同熱處理/熱等靜壓制度處理的室溫/高溫拉伸性能���?��?梢钥吹剑瑢?duì)于 GH3536 與GH3625 合金�����,熱處理雖然導(dǎo)致了強(qiáng)度下降�����,但促進(jìn)了塑性的改善����。對(duì)于 GH4169 合金,熱處理提升了室溫強(qiáng)度��,但塑性有所降低。值得注意的是�,增材制造鎳基高溫合金力學(xué)性能的偏差較大。即便是同一種材料����,不同文獻(xiàn)報(bào)道的力學(xué)性能結(jié)果也存在一定差異。這可能與合金內(nèi)部缺陷與顯微組織隨成形工藝與熱處理/熱等靜壓制度的變化有關(guān)�����。這一現(xiàn)象限制了增材制造鎳基高溫合金的工程應(yīng)用��,是現(xiàn)階段亟需解決的問(wèn)題之一��。

4 ��、增材制造鎳基高溫合金應(yīng)用

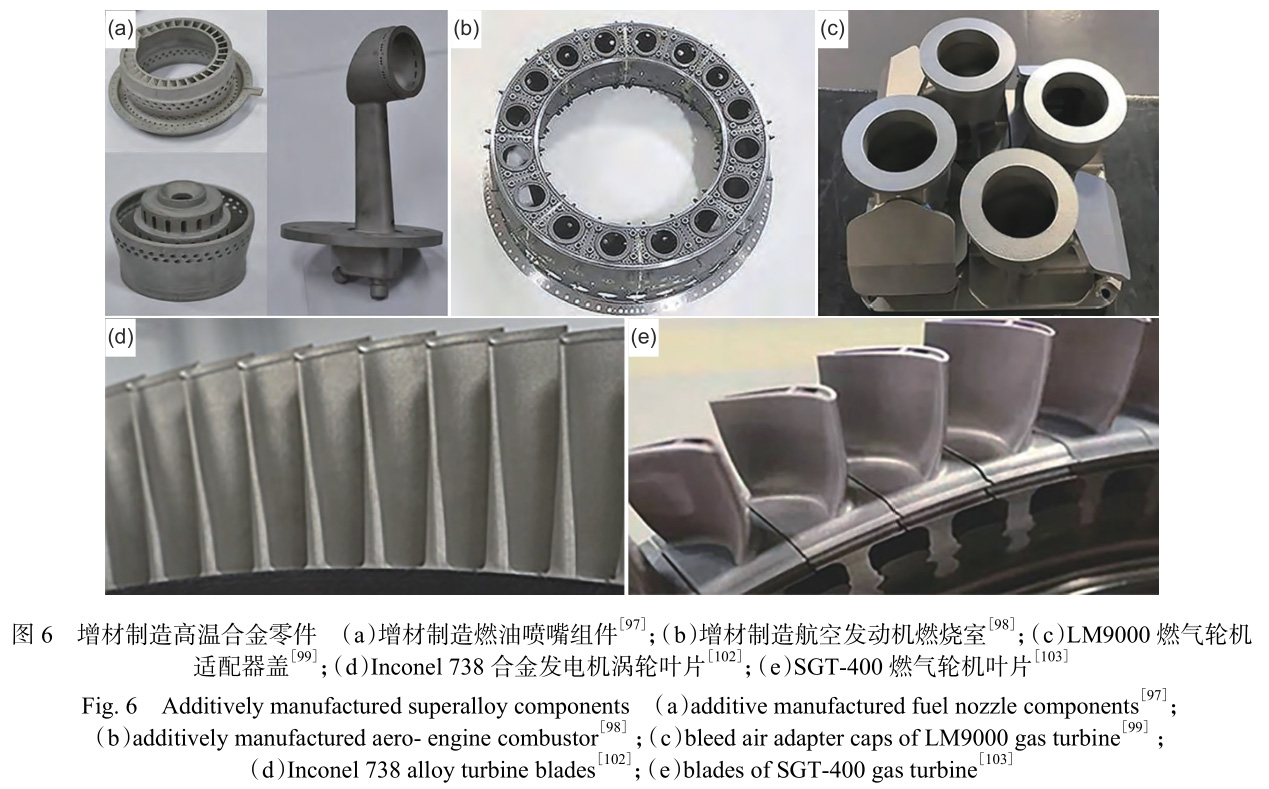

目前���,增材制造鎳基高溫合金構(gòu)件已在航空發(fā)動(dòng)機(jī)及燃?xì)廨啓C(jī)中得到了初步應(yīng)用。在航空發(fā)動(dòng)機(jī)領(lǐng)域��,國(guó)內(nèi)的中國(guó)航發(fā)北京航空材料研究院���、中國(guó)航發(fā)商用航空發(fā)動(dòng)機(jī)有限公司�、北京航空航天大學(xué)、西北工業(yè)大學(xué)�、華中科技大學(xué)、中國(guó)科學(xué)院金屬研究所���、鉑力特等單位對(duì)燃油噴嘴�����、渦流器��、預(yù)旋噴嘴等航空發(fā)動(dòng)機(jī)鎳基高溫合金零件的增材制造進(jìn)行了研究���。采用增材制造技術(shù),可使燃油噴嘴的加工周期由 6 周左右縮短至一周以內(nèi)����,渦流器的加工周期由一個(gè)月左右縮短至 3~5 天[1,97]�。國(guó)際上,賽峰公司采用增材制造技術(shù)成形的鎳基高溫合金渦輪噴嘴通過(guò)了歐洲航空安全局認(rèn)證[3]�。印度斯坦航空公司制造了 25 kN 發(fā)動(dòng)機(jī)的鎳基高溫合金燃燒室機(jī)匣[3]。羅羅公司在進(jìn)行新一代燃燒室制造時(shí)��,首先采用增材制造技術(shù)制造 8 個(gè)燃燒室組件 ����, 再 通 過(guò) 激 光 焊 將 組 件 焊 接 成 1 個(gè) 整 體(圖 6(b))����。與傳統(tǒng)工藝相比����,采用該技術(shù)路線進(jìn)行 燃 燒 室 加 工 僅 需 3.5 個(gè) 月 , 加 工 周 期 縮 短 約70%[98]�����?���;裟犴f爾公司利用電子束熔融技術(shù)制備的 HTF7000 發(fā)動(dòng)機(jī)管腔�����,將原有的 8 個(gè)零件合并為 1 個(gè)����,不但使交貨周期大幅縮短,還降低了制造成本[3]�����。在燃?xì)廨啓C(jī)領(lǐng)域, GE 公司于 2021 年采用激光粉末床熔融成形 LM9000 燃?xì)廨啓C(jī)適配器蓋(圖 6(c))取代了原有的鑄造零件�。這些零件均為一對(duì)一替換,沒有進(jìn)行重新設(shè)計(jì)或零件合并�,僅針對(duì)增材制造工藝進(jìn)行了微小調(diào)整。傳統(tǒng)的鑄造零部件通常需要 12~18 個(gè)月的生產(chǎn)時(shí)間����,而增材制造僅需要 10 個(gè)月時(shí)間,采用增材制造技術(shù)削減了約 35% 的制造成本[99-100]���。美國(guó)橡樹嶺國(guó)家實(shí)驗(yàn)室與 Solar Turbines 合作�,利用電子束熔融技術(shù)制備了 Inconel 738 合金發(fā)電機(jī)渦輪葉片(圖 6(d))��。

他們計(jì)劃后續(xù)利用增材制造技術(shù)成形復(fù)雜內(nèi)部冷卻通道�����,使渦輪機(jī)在更高溫度下運(yùn)行��,以提高發(fā)電效率[101-102]����。為改善鎳基高溫合金渦輪葉片的熱傳遞和沖擊冷卻效果��,德國(guó)西門子公司采用激光粉末床熔融技術(shù)為 SGT-400 燃?xì)廨啓C(jī)制備了具有復(fù)雜內(nèi)部結(jié)構(gòu)的葉片(圖 6(e))�,葉片已在 1250 ℃下通過(guò)了 13000 r/min 旋轉(zhuǎn)速度條件下的滿負(fù)荷考核[1,103-104]��。2017 年�,曼恩機(jī)械在 MGT6100 燃?xì)廨啓C(jī)中使用了增材制造渦輪葉片,率先在世界上實(shí)現(xiàn)了復(fù)雜結(jié)構(gòu)增材制造高溫合金渦輪導(dǎo)向葉片的應(yīng)用[105]��。

5�、 總結(jié)與展望

本文綜述了增材制造鎳基高溫合金在組織、缺陷及性能方面的研究進(jìn)展�����,并介紹了增材制造鎳基高溫合金零件在航空發(fā)動(dòng)機(jī)及燃?xì)廨啓C(jī)中的應(yīng)用情況���?�?梢钥吹剑m然增材制造鎳基高溫合金在理論研究及工程應(yīng)用方面都已取得巨大突破�,但在組織性能調(diào)控及缺陷控制等方面仍存在一定問(wèn)題,要實(shí)現(xiàn)增材制造鎳基高溫合金構(gòu)件在航空發(fā)動(dòng)機(jī)與燃?xì)廨啓C(jī)中更廣泛的應(yīng)用����,還需在以下方面進(jìn)一步開展工作:

(1)設(shè)計(jì)增材制造專用鎳基高溫合金成分合金成分

設(shè)計(jì)要同時(shí)考慮材料的使用性能與加工性能��,加工工藝對(duì)合金成分設(shè)計(jì)具有重要影響�����。目前���,增材制造鎳基高溫合金主要使用傳統(tǒng)牌號(hào)成分,而傳統(tǒng)鎳基高溫合金的成分是基于鑄造�、鍛造等工藝開發(fā)的,并不完全適合增材制造工藝��。

例如����,易開裂是阻礙增材制造鎳基高溫合金應(yīng)用的重要障礙之一,造成這一問(wèn)題的主要原因是部分牌號(hào)鎳基高溫合金的成分在增材制造工藝條件下易形成凝固裂紋及液化裂紋�����。因此����,需要針對(duì)增材制造工藝特點(diǎn)進(jìn)行合金成分設(shè)計(jì),充分發(fā)揮增材制造鎳基高溫合金的性能�。

(2)建立增材制造鎳基高溫合金專用熱處理/熱等靜壓工藝

增材制造過(guò)程具有高溫度梯度���、高冷卻速度和原位熱循環(huán)等特點(diǎn)。與傳統(tǒng)工藝制備鎳基高溫合金相比���,增材制造鎳基高溫合金的顯微組織表現(xiàn)出明顯的各向異性�,且第二相的種類�、含量及分布等也可能存在差異,導(dǎo)致傳統(tǒng)熱處理制度不能完全適用于增材制造鎳基高溫合金����。此外,部分牌號(hào)鎳基高溫合金在增材制造過(guò)程中易形成裂紋�,需要進(jìn)行熱等靜壓處理使裂紋閉合,改善力學(xué)性能�。但是,熱等靜壓引起的顯微組織變化可能導(dǎo)致力學(xué)性能惡化��。因此���,需要依據(jù)增材制造鎳基高溫合金顯微組織與缺陷特點(diǎn)有針對(duì)性地建立熱處理及熱等靜壓工藝����,改善力學(xué)性能�。

(3)開發(fā)單晶高溫合金葉片增材制造技術(shù)

單晶高溫合金具有出色的高溫性能,是制造航空發(fā)動(dòng)機(jī)渦輪葉片的重要材料����。目前,單晶高溫合金葉片主要通過(guò)定向凝固技術(shù)進(jìn)行制備�。但是,鑄造合金組織粗大����、偏析嚴(yán)重、易形成鑄造缺陷�,制約了高溫合金性能的充分發(fā)揮。增材制造過(guò)程中���,熔池具有極高的溫度梯度與冷卻速度��,有助于減少成分偏析�����、疏松以及組織粗大等問(wèn)題���。通過(guò)增材制造技術(shù)進(jìn)行單晶高溫合金葉片制備,可進(jìn)一步提升其力學(xué)性能。然而����,增材制造技術(shù)目前主要用于葉片修復(fù),尚未用于葉片制造���。近年來(lái)�����,有研究發(fā)現(xiàn)使用電子束粉末床熔融技術(shù)及激光光束整形技術(shù)可在多晶合金基體上實(shí)現(xiàn)單晶高溫合金制備�。這一發(fā)現(xiàn)使得直接使用增材制造技術(shù)進(jìn)行單晶高溫合金葉片成形成為可能���,有必要進(jìn)行系統(tǒng)深入研究�。

(4)發(fā)展增材制造實(shí)時(shí)監(jiān)測(cè)控制技術(shù)

增材制造鎳基高溫合金的顯微組織是在快速凝固及原位熱循環(huán)過(guò)程中形成的��,熔池的凝固條件及原位熱循環(huán)的升溫/冷卻速率是增材制造鎳基高溫合金顯微組織的主要影響因素�����,決定了共晶組織���、γ 相���、γ′相�����,析出相等的分布、含量及尺寸等特征�����。此外��,增材制造過(guò)程的溫度場(chǎng)及應(yīng)力場(chǎng)變化對(duì)材料變形開裂具有重要影響���。尤其是對(duì)于易開裂鎳基高溫合金����,需嚴(yán)格控制成形過(guò)程溫度場(chǎng)及應(yīng)力場(chǎng)才能獲得成形質(zhì)量良好的零件�。同時(shí),粉末及其他雜質(zhì)在成形過(guò)程中的飛濺��,可能導(dǎo)致未熔合�����、夾雜、層間開裂等缺陷�。因此,有必要發(fā)展增材制造實(shí)時(shí)監(jiān)測(cè)控制技術(shù)����,依據(jù)溫度、圖像等信號(hào)對(duì)工藝參數(shù)進(jìn)行調(diào)控��,提高增材制造鎳基高溫合金成形質(zhì)量穩(wěn)定性���。

(5)創(chuàng)新增材制造零件內(nèi)表面處理技術(shù)

由于增材制造是逐層疊加過(guò)程�����,因此構(gòu)件表面通常較為粗糙��。雖然通過(guò)改進(jìn)原材料粉末質(zhì)量�、調(diào)整成形過(guò)程零件擺放位置��、優(yōu)化工藝參數(shù)等手段可在一定程度上改善表面質(zhì)量��,但無(wú)法完全解決表面粗糙問(wèn)題����。因此�,增材制造零件必須經(jīng)過(guò)表面處理后方可使用��。增材制造零件通常具有復(fù)雜的內(nèi)部結(jié)構(gòu)�����,而現(xiàn)有的表面處理手段(磨粒流����、電化學(xué)腐蝕��、水射流�、振動(dòng)拋光、噴砂等)難以對(duì)復(fù)雜內(nèi)表面進(jìn)行有效處理��,是限制增材制造零件工程應(yīng)用的關(guān)鍵技術(shù)瓶頸之一�����。因此�����,需要開發(fā)新的內(nèi)表面處理技術(shù)���,促進(jìn)增材制造零件應(yīng)用�。

(6)引入人工智能技術(shù)

人工智能具有強(qiáng)大的數(shù)據(jù)分析處理能力,且自動(dòng)化程度和工作效率更高�。利用人工智能對(duì)設(shè)計(jì)數(shù)據(jù)進(jìn)行分析,能突破人類思維限制�����,進(jìn)一步實(shí)現(xiàn)零件結(jié)構(gòu)的快速優(yōu)化設(shè)計(jì)��。此外��,使用人工智能對(duì)增材制造過(guò)程中產(chǎn)生的數(shù)據(jù)進(jìn)行處理���,預(yù)測(cè)可能產(chǎn)生的缺陷及何時(shí)需要對(duì)設(shè)備進(jìn)行維護(hù)�。不僅可在生產(chǎn)過(guò)程中提前對(duì)工藝參數(shù)進(jìn)行調(diào)整����,還可減少計(jì)劃外停機(jī)時(shí)間,提高產(chǎn)品合格率及生產(chǎn)效率��。同時(shí)���,采用人工智能對(duì)材料數(shù)據(jù)進(jìn)行挖掘���,建立“材料成分-冶金缺陷-力學(xué)性能”關(guān)系����,在實(shí)驗(yàn)之前進(jìn)行成分優(yōu)化篩選�,節(jié)約時(shí)間和資源,加速增材制造專用鎳基高溫合金成分開發(fā)�。因此,有必要將人工智能與增材制造技術(shù)進(jìn)行結(jié)合��,促進(jìn)增材制造技術(shù)快速發(fā)展���。

(7)推動(dòng)增材制造技術(shù)創(chuàng)新

雖然使用現(xiàn)有增材制造技術(shù)生產(chǎn)的零件已在航空發(fā)動(dòng)機(jī)與燃?xì)廨啓C(jī)中實(shí)現(xiàn)應(yīng)用,但未來(lái)仍需進(jìn)一步對(duì)增材制造技術(shù)進(jìn)行改進(jìn)創(chuàng)新�,滿足更大的應(yīng)用需求。通過(guò)增材制造技術(shù)的發(fā)展�����,優(yōu)化零件成形精度�����、改善設(shè)備穩(wěn)定性��、提高制造效率。同時(shí)�����,將增材制造技術(shù)與智能制造�����、數(shù)字化工廠等技術(shù)相結(jié)合�,實(shí)現(xiàn)增材制造的數(shù)字化轉(zhuǎn)型。此外�,還需要考慮環(huán)保和可持續(xù)發(fā)展問(wèn)題,實(shí)現(xiàn)增材制造技術(shù)的綠色化����、環(huán)保化��、可持續(xù)發(fā)展化�。

參考文獻(xiàn):

[1]孫曉峰,宋巍�,梁靜靜,等. 激光增材制造高溫合金材料與工藝研究進(jìn)展 [J]. 金屬學(xué)報(bào)���,2021���,57(11):1471-83.

SUN X F��,SONG W����,LIANG J J�����,et al. Research and development in materials and processes of superalloy fabricated by laser additive manufacturing [J]. Acta

Metallurgica Sinica�����,2021���,57(11):1471-1483.

[2]ZHU A Z,BASOALTO B H��,WARNKEN A N�,et al. A model for the creep deformation behaviour of nickel-based single crystal superalloys[J]. Acta Materialia,

2012����,60(12):4888-900.

[3]劉偉���,李能,周標(biāo)�,等. 復(fù)雜結(jié)構(gòu)與高性能材料增材制造技術(shù)進(jìn)展 [J]. 機(jī)械工程學(xué)報(bào),2019��,55(20):128-151.

LIU W�,LI N,ZHOU B�,et al. Progress in additive man-ufacturing on complex structures and high-performance materials[J]. Journal of Mechanical Engineering,2019��,55(20):128-151.

[4]HUANG S�����,SUN B����,GUO S. Microstructure and prop-erty evaluation of TA15 titanium alloy fabricated by selective laser melting after heat treatment[J]. Optics & Laser Technology,2021���,144:107422.

[5]TAN C�����,WENG F�,SUI S,et al. Progress and perspec-tives in laser additive manufacturing of key aeroengine materials[J]. International Journal of Machine Tools and Manufacture�,2021,170:103804.

[6]YONG C K����,GIBBONS G J,WONG C C����,et al. A criti-cal review of the material characteristics of additive manufactured IN718 for high-temperature application [J]. Metals,2020�����,10(12):1576.

[7]冀國(guó)鋒��,李俊勵(lì)�,楊進(jìn)飛. 風(fēng)扇/壓氣機(jī)增材制造技術(shù)的應(yīng)用與發(fā)展趨勢(shì) [J]. 航空動(dòng)力����,2020(2):75-78.

JI G F,LI J L,YANG J F. Additive manufacturing tech-nology for fan and compressor[J]. Aerospace Power��,2020(2):75-78.

[8]王天元��,黃帥��,周標(biāo)��,等. 航空裝備激光增材制造技術(shù)發(fā)展及路線圖 [J]. 航空材料學(xué)報(bào)�,2023,43(1):1-17.

WANG T Y���,HUANG S���,ZHOU B,et al. Development and roadmap of laser additive manufacturing technology for aviation equipment[J]. Journal of Aeronautical

Materials�,2023,43(1):1-17.

[9]KURZ W�����, GIOVANOLA B���, TRIVEDI R. Theory of microstructural development during rapid solidification [J]. Acta Metallurgica��,1986��,34(5):823-830.

[10]G?UMANN M��,HENRY S�����,CLéTON F����,et al. Epitax-ial laser metal forming: analysis of microstructure for-mation[J]. Materials Science and Engineering: A,1999����,271(1):232-241.

[11]G?UMANN M, BEZEN?ON C���, CANALIS P����, et al.Single-crystal laser deposition of superalloys:processing–microstructure maps[J]. Acta Materialia�����,2001�����,49(6):1051-1062.

[12]WILSON J M����,PIYA C,SHIN Y C���,et al. Remanufac-turing of turbine blades by laser direct deposition with its energy and environmental impact analysis[J]. Journal of Cleaner Production���,2014,80:170-178.

[13]ZHANG D���,WEN N�����,CAO X����,et al. Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy[J]. Materials Science and Engi-neering:A��,2015,644:32-40.

[14]XU X���, GANGULY S���, DING J, et al. Enhancing mechanical properties of wire + arc additively manufac-tured Inconel 718 superalloy through in-process thermo-mechanical processing[J]. Materials & Design���, 2018����,160:1042-1051.

[15]TAYON W A�,SHENOY R,REDDING M R����,et al. Cor-relation between microstructure and mechanical proper-ties in an Inconel 718 deposit produced via electron beam freeform fabrication[J]. Journal of Manufacturing Science and Engineering,2014���,136:061005.

[16]CHLEBUS E���,GRUBER K,KUZNICKA B�����,et al. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting[J]. Materials Science and Engineering: A,2015����,639:647-655.

[17]DENG D��, RU L P�����, BRODIN H��, et al. Microstructure and mechanical properties of Inconel 718 produced by selective laser melting: sample orientation dependence and effects of post heat treatments[J]. Materials Sci-ence and Engineering:A�,2018,713:294-306.

[18]JINOOP A N���,PAUL C P�,BINDRA K S. Laser-assisted directed energy deposition of nickel super alloys: a review[J]. Proceedings of the Institution of Mechanical Engineers��,Part L���,2019����,233(11):2376-400.

[19]鄭寅嵐,何艷麗����,陳曉暉,等. 選區(qū)激光熔化成形GH3536 合金的高溫拉伸性能及斷裂行為分析 [J]. 中國(guó)激光�����,2020��,47(8):0802008.

ZHENG Y L����,HE Y L,CHEN X H��,et al. Elevated-tem-perature tensile properties and fracture behavior of GH3536 alloy formed via selective laser melting[J].

Chinese Journal of Lasers����,2020,47(8):0802008.

[20]閔師領(lǐng)��,侯娟����,張愷�����,等. 激光粉末床技術(shù)制造 GH3536合 金 研 究 現(xiàn) 狀 [J]. 激 光 與 光 電 子 學(xué) 進(jìn) 展 ����, 2021���,58(17):98-109.

MIN S L,HOU J�����,ZHANG K�����,et al. Laser powder bed fusion of GH3536 alloy[J]. Laser & Optoelectronics Progress�,2021,58(17):98-109.

[21]WONG H���,DAWSON K�,RAVI G A,et al. Multi-laser powder bed fusion benchmarking-initial trials with Inconel 625[J]. The International Journal of Advanced Manufacturing Technology����,2019,105(7):2891-906.

[22]張潔��,李帥�����,魏青松�,等. 激光選區(qū)熔化 Inconel625 合金開裂行為及抑制研究 [J]. 稀有金屬,2015��,39(11):961-966.

ZHANG J�,LI S,WEI Q S�����,et al. Cracking behavior and inhibiting process of Inconel 625 alloy formed by selec-tive laser melting[J]. Rare Metals�,2015,39(11):961-966.

[23]KARMUHILAN M�,KUMANAN S. A review on addi-tive manufacturing processes of Inconel 625[J]. Journal of Materials Engineering and Performance, 2021,31(4):2583-2592.

[24]WANG J��,WANG H����,GAO H,et al. Effect of microseg-regation behaviors on solidification microstructure of IC10 superalloy fabricated by directed energy deposi-tion[J]. Additive Manufacturing�,2022,59:103158.

[25]HOSSEINI E��,POPOVICH V A. A review of mechani-cal properties of additively manufactured Inconel 718[J]. Additive Manufacturing�����,2019�����,30:100877.

[26]NI M���,LIU S,CHEN C����,et al. Effect of heat treatment on the microstructural evolution of a precipitation-hard-ened superalloy produced by selective laser melting[J].Materials Science and Engineering:A,2019,748:275-285.

[27]TOMUS D��, TIAN Y���, ROMETSCH P A�, et al. Influ-ence of post heat treatments on anisotropy of mechani-cal behaviour and microstructure of Hastelloy-X parts produced by selective laser melting[J]. Materials Sci-ence and Engineering:A�����,2016��,667:42-53.

[28]李雅莉��,雷力明�����,侯慧鵬��,等. 熱工藝對(duì)激光選區(qū)熔化Hastelloy X 合金組織及拉伸性能的影響 [J]. 材料工程����,2019,47(5):100-106.

LI Y L��,LEI L M,HOU H P�,et al. Effect of heat pro-cessing on microstructures and tensile properties of selective laser melting Hastelloy X alloy[J]. Journal of

Materials Engineering,2019�����,47(5):100-106.

[29]TIAN Z�����,ZHANG C�,WANG D,et al. A review on laser powder bed fusion of Inconel 625 nickel-based alloy[J].Applied Sciences���,2019��,10(1):81.

[30]WANG Y���,LI N�,JIA C,et al. Effects of solution treat-ment on the microstructural evolution and tensile proper-ties of GH3230 superalloy manufactured by laser melt-ing deposition [J]. Materials Characterization 2022�����,194:112339.

[31]黃 文 普 , 喻 寒 琛 ����, 殷 杰 , 等 . 激 光 選 區(qū) 熔 化 成 形K4202 鎳基鑄造高溫合金的組織和性能 [J]. 金屬學(xué)報(bào)�����,2016���,52(9):1089-1095.

HUANG W P��,YU H C��,YIN J��,et al. Microstructure and mechanical properties of K4202 cast nickle based super-alloy fabricatied by selective laser melting[J]. Acta

Metallurgica Sinica��,2016��,52(9):1089-1095.

[32]JODI D E���,KITASHIMA T,KOIZUMI Y����,et al. Manu-facturing single crystals of pure nickel via selective laser melting with a flat-top laser beam[J]. Additive Manu-facturing Letters�,2022�,3:100066.

[33]RAMSPERGER M, KORNER C. Selective electron beam melting of the single crystalline nickel-base super-alloy CMSX-4: from columnar grains to a single crystal [C]//Superalloys 2016:Proceedings of the 13th Interna-tional Symposium on Superalloys. Nürnberg: [s.n.],2016: 341-349

[34]K?RNER C�, RAMSPERGER M, MEID C�����, et al.Microstructure and mechanical properties of CMSX-4 single crystals prepared by additive manufacturing[J].

Metallurgical and Materials Transactions A�, 2018,49(9):3781-3792.

[35]FERNANDEZ-ZELAIA P��, KIRKA M M�, ROSSY A M, et al. Nickel-based superalloy single crystals fabri-cated via electron beam melting[J]. Acta Materialia�����,

2021����,216:117133.

[36]CHAUVET E����,TASSIN C��,BLANDIN J J�,et al. Produc-ing Ni-base superalloys single crystal by selective elec-tron beam melting[J]. Scripta Materialia��,2018�����,152:15-19.

[37]LI Y��,YU Y F�,WANG Z B,et al. Additive manufactur-ing of nickel-based superalloy single crystals with IN-738 alloy[J]. Acta Metallurgica Sinica�����,2022��,35:369-374.

[38]LIANG Y J��,CHENG X�����,WANG H M. A new microseg-regation model for rapid solidification multicomponent alloys and its application to single-crystal nickel-base superalloys of laser rapid directional solidification[J].Acta Materialia,2016��,118:17-27.

[39]LIANG Y J�����,LI J�����,LI A�,et al. Solidification path of sin-gle-crystal nickel-base superalloys with minor carbon additions under laser rapid directional solidification con-ditions[J]. Scripta Materialia,2017��,127:58-62.

[40]LIANG Y J����,LI J,LI A�,et al. Experimental optimiza-tion of laser additive manufacturing process of single-crystal nickel-base superalloys by a statistical experi-ment design method[J]. Journal of Alloys and Com-pounds,2017����,697:174-81.

[41]LIANG Y J,LI A,CHENG X�,et al. Prediction of pri-mary dendritic arm spacing during laser rapid direc-tional solidification of single-crystal nickel-base superal-loys[J]. Journal of Alloys and Compounds��,2016�,688:133-142.

[42]LIANG Y J,CHENG X�����,LI J����,et al. Microstructural con-trol during laser additive manufacturing of single-crystal nickel-base superalloys: new processing–microstructure maps involving powder feeding[J]. Materials &Design,2017���,130:197-207.

[43]梁靜靜���,楊彥紅,周亦胄����,等. 激光立體成形鎳基單晶高溫合金顯微組織研究 [J]. 稀有金屬材料與工程,2017�,46(12):3753-3759.

LIANG J J,YANG Y H��,ZHOU Y Z,et al. Microstruc-tures of nickel-based single-crystal superalloy prepared by laser solid forming[J]. Rare Metal Materials and

Engineering���,2017�����,46(12):3753-3759.

[44]CI S��,LIANG J����,LI J�����,et al. Microstructure and tensile properties of DD32 single crystal Ni-base superalloy repaired by laser metal forming[J]. Materials Science and Technology���,2020����,45:23-34.

[45]ROTTWINKEL B��,N?LKE C,KAIERLE S����,et al. Laser cladding for crack repair of CMSX-4 single-crystalline turbine parts[J]. Lasers in Manufacturing and Materials Processing,2017�,4(1):13-23.

[46]WANG C����, LI Q, ZHOU X�����, et al. Contrastive studies between laser repairing and plasma arc repairing on sin-gle-crystal Ni-based superalloy[J]. Materials��, 2019����,12(7):1172.

[47]ZHANG D,LIU W�,LI Y,et al. In situ observation of crystal rotation in Ni-based superalloy during additive manufacturing process[J]. Nature Communications��,2023���,14(1):2961.

[48]SAMES W J���,UNOCIC K A���,DEHOFF R R,et al. Ther-mal effects on microstructural heterogeneity of Inconel 718 materials fabricated by electron beam melting[J].Journal of Materials Research����, 2014, 29(17) : 1920-1930.

[49]ARRIZUBIETA J I�,LAMIKIZ A,CORTINA M�����,et al.Hardness�, grain size and porosity formation prediction on the laser metal deposition of AISI 304 stainless

steel[J]. International Journal of Machine Tools and Manufacture,2018����,135:53-64.

[50]高祥熙,楊平華�����,喬海燕,等. 基于 μCT 表征的 SLM成 形 GH3536 高 溫 合 金 缺 陷 特 征 [J]. 材 料 工 程 ����,2022,50(10):63-72.

GAO X X�,YANG P H,QIAO H Y��,et al. Defect charac-teristics within SLM-fabricated GH3536 superalloy dependence on μCT characterization[J]. Journal of

Materials Engineering���,2022,50(10):63-72.

[51]HAN Q�����, MERTENS R����, MONTERO-SISTIAGA M L,et al. Laser powder bed fusion of Hastelloy X:effects of hot isostatic pressing and the hot cracking

mechanism[J]. Materials Science and Engineering: A��,2018�,732:228-239.

[52]GUO B,ZHANG Y�,YANG Z�����,et al. Cracking mecha-nism of Hastelloy X superalloy during directed energy deposition additive manufacturing[J]. Additive Manu-facturing��,2022�,55:102792.

[53]FU J��,LI H�����,SONG X��,et al. Multi-scale defects in pow-der-based additively manufactured metals and alloys[J].Journal of Materials Science & Technology�,2022,122:165-199.

[54]ZHOU Z�����, LEI Q�, YAN Z, et al. Effects of process parameters on microstructure and cracking susceptibil-ity of a single crystal superalloy fabricated by directed energy deposition[J]. Materials & Design���, 2020�, 198:109296.

[56]RONG P,WANG N���,WANG L���,et al. The influence of grain boundary angle on the hot cracking of single crystal superalloy DD6[J]. Journal of Alloys & Compounds,2016�����,676:181-186.

[57]LU N�,LEI Z,HU K���,et al. Hot cracking behavior and mechanism of a third-generation Ni-based single-crystal superalloy during directed energy deposition[J]. Addi-tive Manufacturing,2020�,34:101228.

[58]CHANDRA S,TAN X����,NARAYAN R L,et al. A gen-eralised hot cracking criterion for nickel-based superal-loys additively manufactured by electron beam

melting[J]. Additive Manufacturing���,2021����,37:101633.

[59]於之杰,徐碧涵���,王向盈 等. 航空增材制造技術(shù)中的跨尺度力學(xué)研究進(jìn)展 [J]. 航空材料學(xué)報(bào)�����,2023����,5(43):1-9.

YU Z J�����,XU B H�����,WANG X Y����,et al. Progress of cross-scale mechanics in additive manufacturing technology for aeronautical application[J]. Journal of Aeronautical

Materials,2023�,5(43):1-9.

[60]萬(wàn)宏遠(yuǎn)��,劉壯壯�,韓泉泉�����,等. 激光增材制造高溫合金抗 開 裂 行 為 研 究 進(jìn) 展 [J]. 航 空 科 學(xué) 技 術(shù) ����, 2022,33(9):26-42.

WAN H Y�����,LIU Z Z�,HAN Q Q,et al. Laser additive manufacturing of cracking-resistant superalloys[J].Aeronautical Science & Technology�,2022,33(9):26-42.

[61]CLOOTS M���, UGGOWITZER P J, WEGENER K.Investigations on the microstructure and crack forma-tion of IN738LC samples processed by selective laser

melting using Gaussian and doughnut profiles[J]. Mate-rials & Design����,2016���,89:770-784.

[62]WU Y,SUN B B��,CHEN B Q�����,et al. Cracking mecha-nism of GH5188 alloy during laser powder bed fusion additive manufacturing[J]. Materials Characterization��,2024�,207:113548.

[63]SANCHEZ S, SMITH P��, XU Z�, et al. Powder bed fusion of nickel-based superalloys: a review, Interna-tional Journal of Machine Tools and Manufacture��,2021�����,165:103729.

[64]KONTIS P�,CHAUVET E,PENG Z,et al. Atomic-scale grain boundary engineering to overcome hot-cracking in additively-manufactured superalloys[J]. Acta Materi-alia����,2019,177:209-221.

[65]ZHOU Z���,HUANG L��,SHANG Y�,et al. Causes analy-sis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufac-turing[J]. Materials & Design��,2018�,160:1238-1249.

[66]XU J, DING Y��, GAO Y���, et al. Grain refinement and crack inhibition of hard-to-weld Inconel 738 alloy by altering the scanning strategy during selective laser melt-ing[J]. Materials & Design����,2021�����,209:109940.

[67]TOMUS D���,ROMETSCH P A���,HEILMAIER M,et al.Effect of minor alloying elements on crack-formation characteristics of Hastelloy-X manufactured by selec-

tive laser melting[J]. Additive Manufacturing��, 2017�,16:65-72.

[68]HARRISON N J,TODD I���,MUMTAZ K. Reduction of micro-cracking in nickel superalloys processed by selec-tive laser melting: a fundamental alloy design

approach[J]. Acta Materialia���,2015,94:59-68.

[69]TANG Y T�,PANWISAWAS C,GHOUSSOUB J N���,et al. Alloys-by-design:application to new superalloys for additive manufacturing[J]. Acta Materialia�����,2021���,202:417-436.

[70]HAN Q���,GU Y,SETCHI R����,et al. Additive manufactur-ing of high-strength crack-free Ni-based Hastelloy X superalloy[J]. Additive Manufacturing, 2019�, 30:100919.

[71]CHENG X,ZHAO Y�,QIAN Z,et al. Crack elimination and mechanical properties enhancement in additive man-ufactured Hastelloy X via in-situ chemical doping of Y2O3[J]. Materials Science and Engineering:A����,2021,824:141867.

[72]POPOVICH V A���,BORISOV E V����,POPOVICH A A�,et al. Impact of heat treatment on mechanical behaviour of Inconel 718 processed with tailored microstructure by selective laser melting[J]. Materials & Design, 2017��,131:12-22.

[73]WANG F. Mechanical property study on rapid additive layer manufacture Hastelloy? X alloy by selective laser melting technology[J]. The International Journal of Advanced Manufacturing Technology, 2012����, 58(5) :545-551.

[74]WANG P��,ZHANG B��,TAN C C���,et al. Microstructural characteristics and mechanical properties of carbon nan-otube reinforced Inconel 625 parts fabricated by selec-tive laser melting[J]. Materials and Design����,2016�,112:290-299.

[75]宋衎,喻凱����,林鑫,等. 熱處理態(tài)激光立體成形 Inconel718 高 溫 合 金 的 組 織 及 力 學(xué) 性 能 [J]. 金 屬 學(xué) 報(bào) �����,2015�,51(8):935-942.

SONG K���, YU K, LIN X����, et al. Microstructure and mechanical properties of heat treatment laser solid form-ing superalloy Inconel 718[J]. Acta Metallurgica

Sinica,2015�,51(8):935-942.

[76]STR?SSNER J,TEROCK M�����,GLATZEL U. Mechani-cal and microstructural investigation of nickel-based superalloy IN718 manufactured by selective laser melt-ing (SLM)[J]. Advanced Engineering Materials����,2015,17(8):1099-1105.

[77]SANCHEZ-MATA O�����, MU?IZ-LERMA J A�����, WANG X����, et al. Microstructure and mechanical properties at room and elevated temperature of crack-free Hastelloy Xfabricated by laser powder bed fusion[J]. Materials Sci-ence and Engineering:A�����,2020�����,780:139177.

[78]MONTERO-SISTIAGA M L,LIU Z�,BAUTMANS L,et al. Effect of temperature on the microstructure and tensile properties of micro-crack free hastelloy X pro-duced by selective laser melting[J]. Additive Manufac-turing�����,2020��,31:100995.

[79]NGUEJIO J���, SZMYTKA F���, HALLAIS S, et al. Com-parison of microstructure features and mechanical prop-erties for additive manufactured and wrought nickel alloys 625[J]. Materials Science and Engineering����,2019���,764:138214.

[80]張國(guó)棟,許喬郅�,鄭濤,等. 航空裝備電子束增材制造技術(shù)發(fā)展及路線圖 [J]. 航空材料學(xué)報(bào)����,2023,43(1):28-38.

ZHANG G D���,XU Q Z�,ZHENG T�����,et al. Technology development and roadmap of electron beam additive manufacturing for aviation equipments[J]. Journal of

Aeronautical Materials���,2023�,43(1):28-38.

[81]劉凱. 熱等靜壓工藝對(duì) SLM 成形 GH3536 合金的組織及性能影響 [D]. 北京:機(jī)械科學(xué)研究總院���,2018.

LIU K. Impact of HIP on the structure and property of GH3536 alloy formed by SLM [D]. Beijing:Academy of Machinery Science & Technology�,2018.

[82]BEAN G E, MCLOUTH T D����, WITKIN D B, et al.Build orientation effects on texture and mechanical prop-erties of selective laser melting Inconel 718[J]. Journal of Materials Engineering and Performance����, 2019, 28:1942-1949.

[83]NI M����, CHEN C����, WANG X, et al. Anisotropic tensile behavior of in situ precipitation strengthened Inconel 718 fabricated by additive manufacturing[J]. Materials Science and Engineering:A�����,2017���,701:344-351.

[84]GALLMEYER T G�����,MOORTHY S�����,KAPPES B B�����,et al. Knowledge of process-structure-property relation-ships to engineer better heat treatments for laser powder bed fusion additive manufactured Inconel 718[J]. Addi-tive Manufacturing���,2020�����,31:100977.

[85]TROSCH T�, STROESSNER J�����, YOELKL R�, et al.Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and cast-ing[J]. Materials Letters,2016�����,164:428-431.

[86]KIRKA M M,MEDINA F��,DEHOFF R����,et al. Mechani-cal behavior of post-processed Inconel 718 manufac-tured through the electron beam melting process[J].Materials Science and Engineering:A,2017���,680:338-346.

[87]STRONDL A���,PALM M,GNAUK J�,et al. Microstruc-ture and mechanical properties of nickel based superal-loy IN718 produced by rapid prototyping with electron beam melting (EBM)[J]. Materials Science and Tech-nology,2011���,27(5):876-883.

[88]XU X,GANGUL S�����,DING J�,et al. Enhancing mechani-cal properties of wire+arc additively manufactured INCONEL 718 superalloy through in-process thermo-mechanical processing[J]. Materials & Design, 2018,160:1042-1051.

[89]ALONSO U�����,VEIGA F��,SUáREZ A�����,et al. Characteriza-tion of Inconel 718? superalloy fabricated by wire arc additive manufacturing:effect on mechanical properties and machinability[J]. Journal of Materials Research and Technology���,2021���,14:2665-2676.

[90]BLACKWELL P L. The mechanical and microstruc-tural characteristics of laser-deposited IN718[J]. Jour-nal of Materials Processing Technology,2005��,

170(1/2):240-246.

[91]ZHAO X�����,CHEN J���,LIN X�,et al. Study on microstruc-ture and mechanical properties of laser rapid forming Inconel 718[J]. Materials Science and Engineering:A,2008���,478:119-124.

[92]GAO Y����,ZHANG D�����,CAO M�����,et al. Effect of δ phase on high temperature mechanical performances of Inconel 718 fabricated with SLM process[J]. Materials Science and Engineering:A�,2019,767:138327.

[93]KUO Y L����, KAKEHI K. Influence of powder surface contamination in the Ni-based superalloy alloy718 fabri-cated by selective laser melting and hot isostatic press-ing[J]. Metals,2017���,7(9):367.

[94]ZHANG Y,YANG L��,LU W,et al. Microstructure and elevated temperature mechanical properties of IN718 alloy fabricated by laser metal deposition[J]. Materials Science and Engineering:A���,2020�,771:138580.

[95]KREITCBERG A���,BRAILOVSKI V�����,TURENNE S�,et al. Influence of thermo- and HIP treatments on the microstructure and mechanical properties of IN625 alloy

parts produced by selective laser melting:a comparative study[J]. Materials Science Forum�, 2016, 879: 1008-1013.

[96]楊啟云�����,吳玉道����,沙菲. 選區(qū)激光熔化成形 Inconel625合金的顯微組織及力學(xué)性能 [J]. 機(jī)械工程材料,2016���,40(6):83-87.

YANG Q Y���, WU Y D���, SHA F. Microstructure and mechanical properties of Inconel 625 alloy manufac-tured by selective laser melting[J]. Materials for

Mechanical Engineering,2016�,40(6):83-87.

[97]何艷麗,廖煥文��,王祿秀. 商用航空發(fā)動(dòng)機(jī)金屬增材制造技術(shù)及裝備應(yīng)用 [J]. 航空制造技術(shù)�����,2014�����,22:47-51.

HE Y L����,LIAO H W,WANG L X�����,et al. Application of technology and equipment for metallic additive manu-facturing in commercial aeroengine[J]. Aeronautical

Manufacturing Technology��,2014���,22:47-51.

[98]楊謙. 增材制造在航空發(fā)動(dòng)機(jī)燃燒室中的應(yīng)用 [J]. 航空動(dòng)力�����,2018(4):26-29.

YANG Q. Additive manufacturing for combustors[J].Aerospace Power���,2018(4):26-29.

[99]3DPRINTINGINDUSTRY. GE cuts costs by 35% in move from casting to 3D printing technology [EB/OL]2021. https://3dprintingindustry.com/news/ge-cuts-costs-by-35-in-move-from-casting-to-3d-printing-technology-189798/.

[100]GE. GE Aviation and GE Additive engineers have switched four existing parts from castings to metal 3D printing—and see potential for hundreds more [EB/OL]2021. https://www.ge.com/additive/blog/ge-aviation-and-ge-additive-engineers-have-switched-four-existing-parts-castings-metal-3d.

[101]ADDITIVEMANUFACTURING. 3D printed turbine blades for more efficient power generation: the cool parts show #35 [EB/OL] 2021. https://www.additive-

manufacturing.media/articles/3d-printed-turbine-blades-for-more-efficient-power-generation-the-cool-parts-show-35.

[102]ADDITIVEMANUFACTURING. AM will change power generation, but needs to prove itself first [EB/OL]2022.https://www.additivemanufacturing.

media/articles/am-will-change-power-generation-but-needs-to-prove-itself-first.

[103]楊膠溪�����,吳文亮�,王長(zhǎng)亮,等. 激光選區(qū)熔化技術(shù)在航空航天領(lǐng)域的發(fā)展現(xiàn)狀及典型應(yīng)用 [J]. 航空材料學(xué)報(bào)�,2021,41(2):1-15.

YANG J X���,WU W L����,WANG C L��,et al. Development status and typical application of selective laser melting technology applications in aerospace field[J]. Journal of Aeronautical Materials,2021����,41(2):1-15.

[104]吳宏超,袁浩���,魏佳明�����,等. 增材制造在燃?xì)廨啓C(jī)研發(fā)及生產(chǎn)中的應(yīng)用 [J]. 航空動(dòng)力���,2022(2):26-28.

WU H C,YUAN H���,WEI J M�,et al. The application of additive manufacturing technology in gas turbine research�����,development and manufacture [J]. Aerospace

Power��,2020(2):26-28.

[105]3DPRINTINGINDUSTRY. Man diesel uses metal am for serial turbine production [EB/OL] 2017. https://www.3dprintingmedia.network/man-diesel-uses-metal-serial-turbine-production/.

收稿日期:2023-12-01;修訂日期:2024-01-01

基金項(xiàng)目:國(guó) 家 科 技 重 大 專 項(xiàng) 項(xiàng) 目 (J2019-Ⅶ-0003-0143�����,Y2019-Ⅶ-0011-0151�����,J2022-Ⅶ-0002)�;國(guó)家自然科學(xué)基金(51875541�,52005465);基礎(chǔ)加強(qiáng)計(jì)劃技術(shù)領(lǐng)域基金(2021-JCJQ-JJ-1095)�;中國(guó)航發(fā)自主創(chuàng)新專項(xiàng)資金(ZZCX-2021-013)

通訊作者:陳冰清(1984—),女�����,博士���,研究員���,研究方向?yàn)樵霾闹圃欤?lián)系地址:北京市海淀區(qū)溫泉鎮(zhèn)環(huán)山村 8 號(hào)(100095)�����,E-mail:hwtkjcbq1984@163.com

相關(guān)鏈接